Bag Filter Design

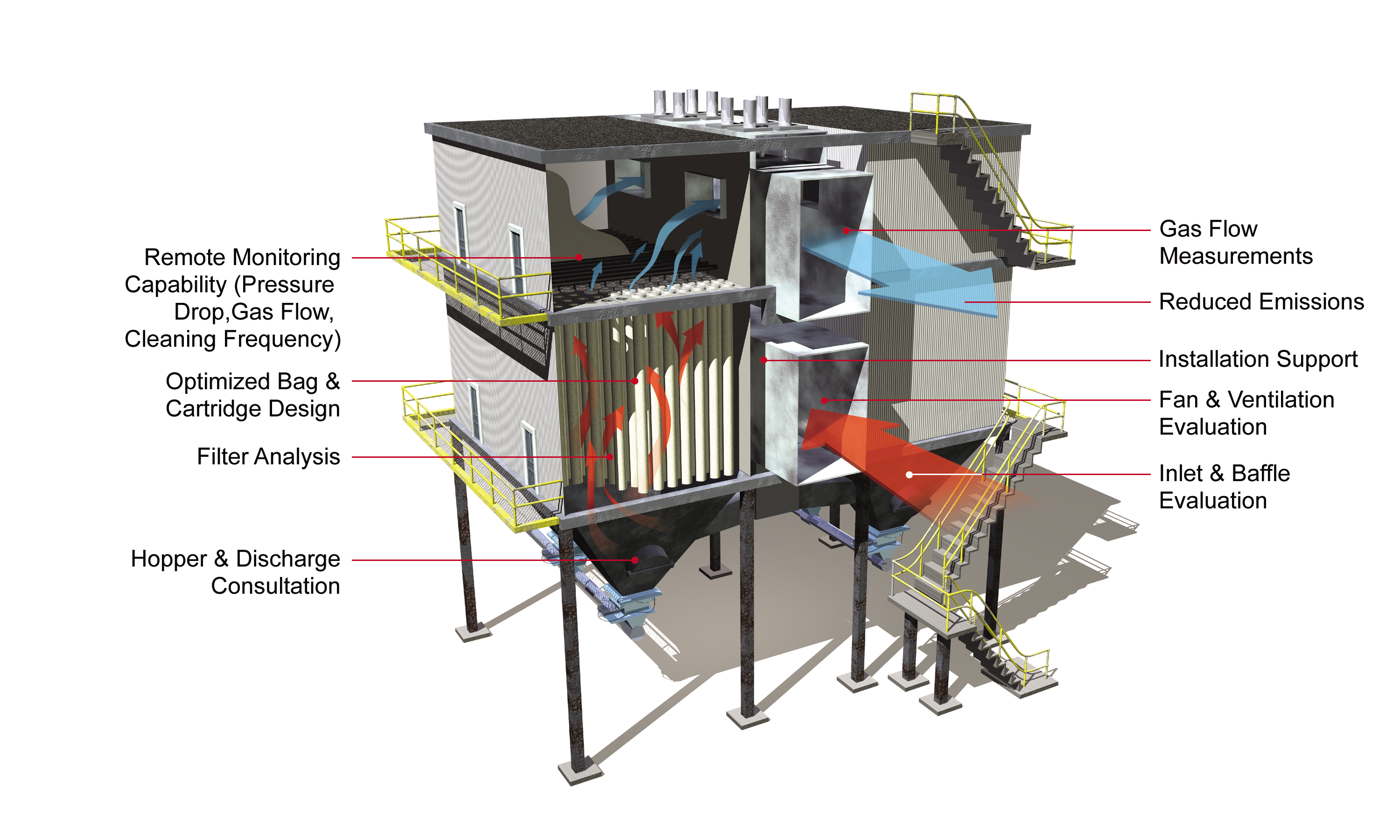

Bag filter design. I am new member and kindly if there are any calculations or design corelations of design the bag filter. Although an old technology a well sized baghouse with modern filtration media. The filters in the EHT-Bag Filter are rigid with a consistency like cardboard and they dont need a cage inside as they are self-supporting.

BAG FILTERS CONTENTS 1. When it comes to dedusting a gas stream cartridges filters can have strong advantages compared to conventional bag filters especially in terms of filtration area in a reduced volume. The bag filters should be operated at temperatures below 200C and preferably between 120C and 150C depending on the material used to construct the filter bags.

Respiratory protection for maintenance personnel may be required when replacing fabric. 1 2 3 4 5 One of several possible configurations for our Dual-. Enter the ACFM of Air Sq.

Bag Filter Gas Suspension Absorber Reagent Dosing for a. The negative pressure estimation. THE MECHANXSMOF PARTICLE CAPTURE 3.

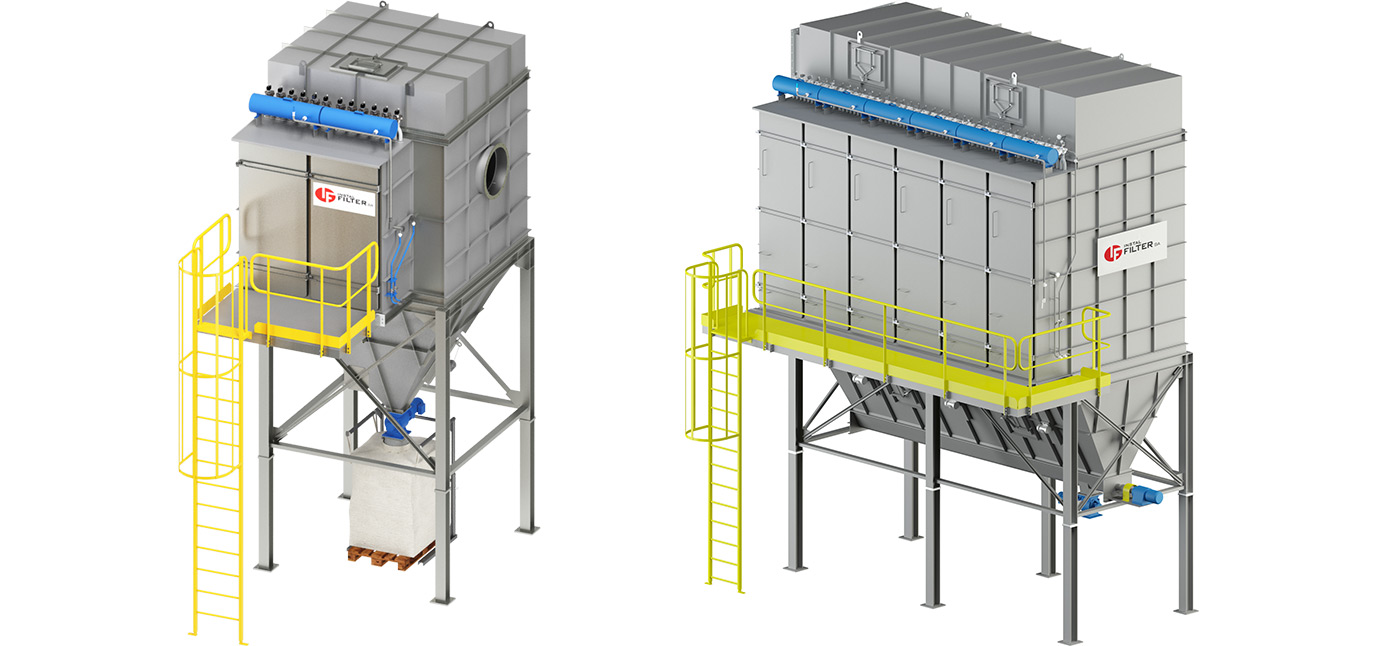

Filter Designs are small enough to care and large enough to cope. The velocity of the air suction. Baghouse filter working principle.

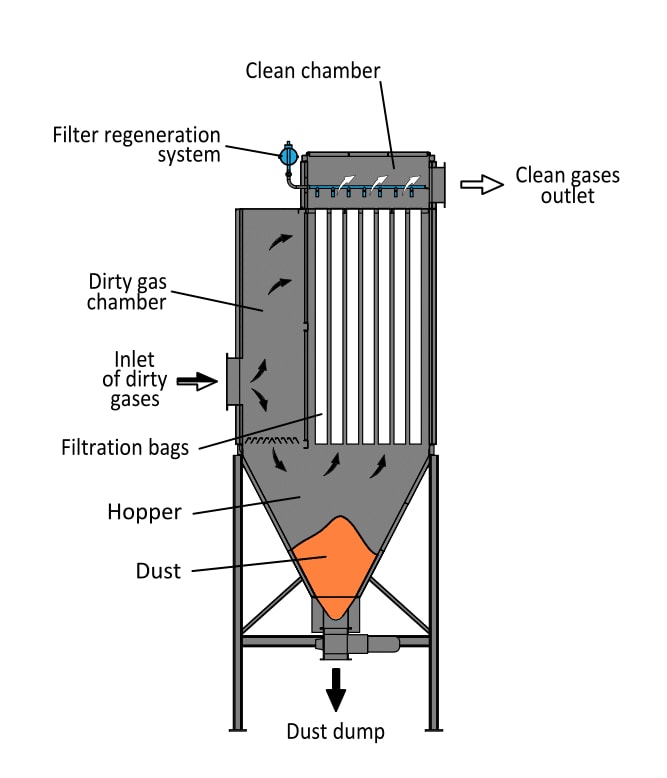

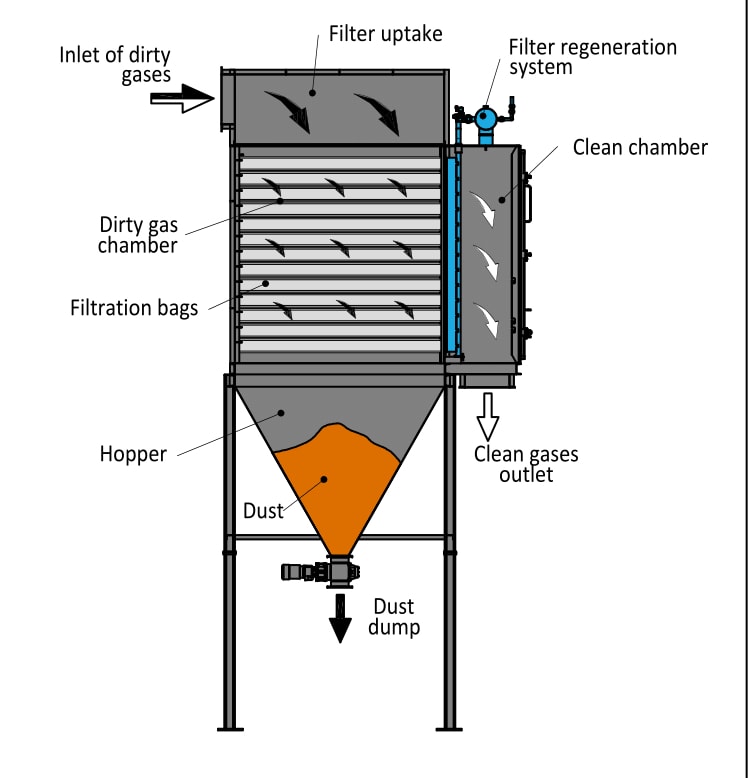

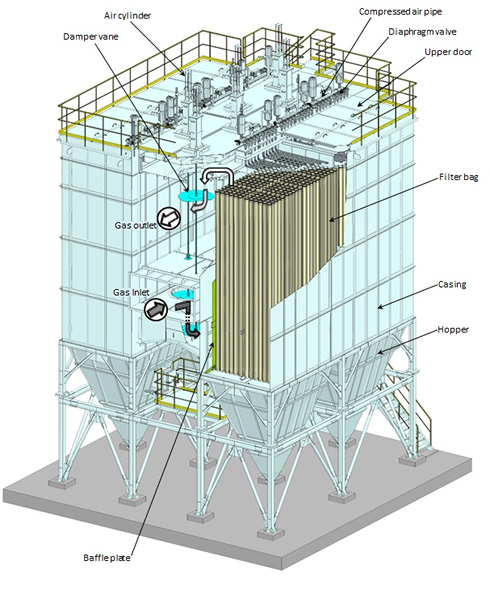

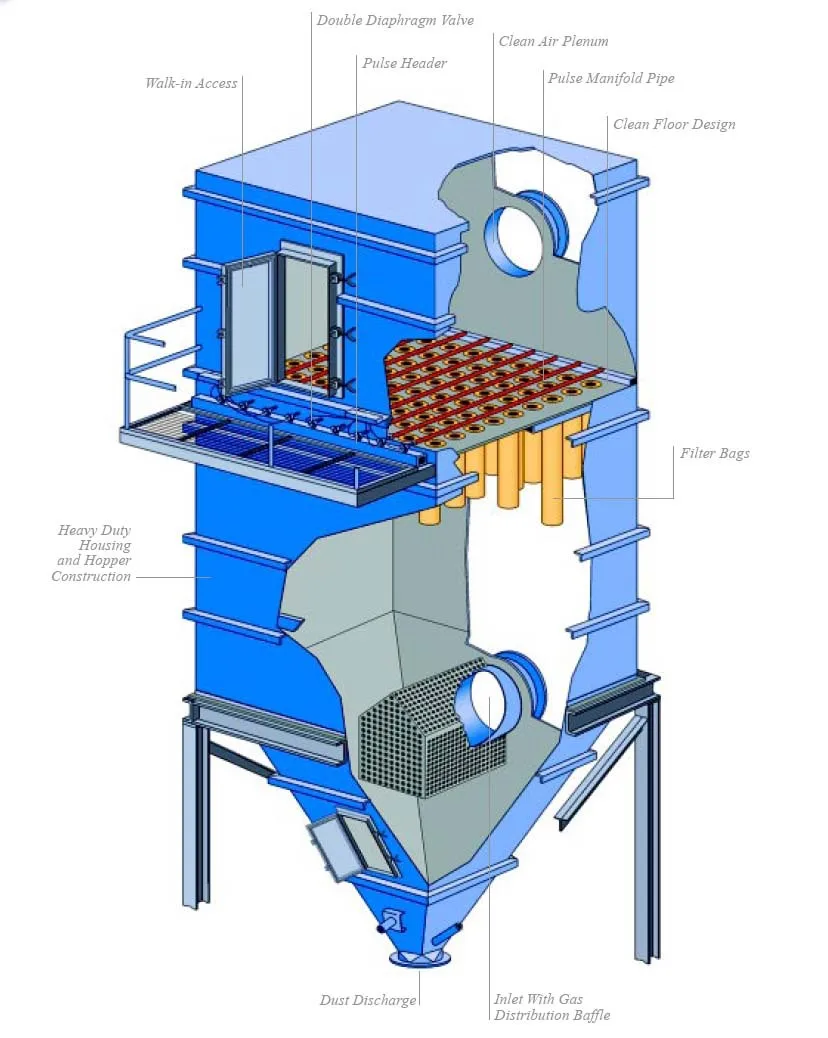

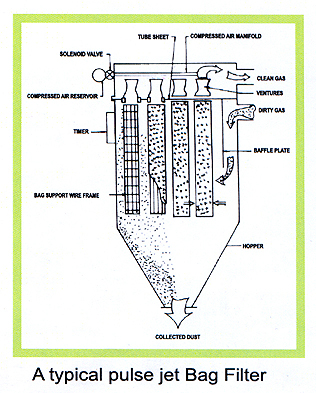

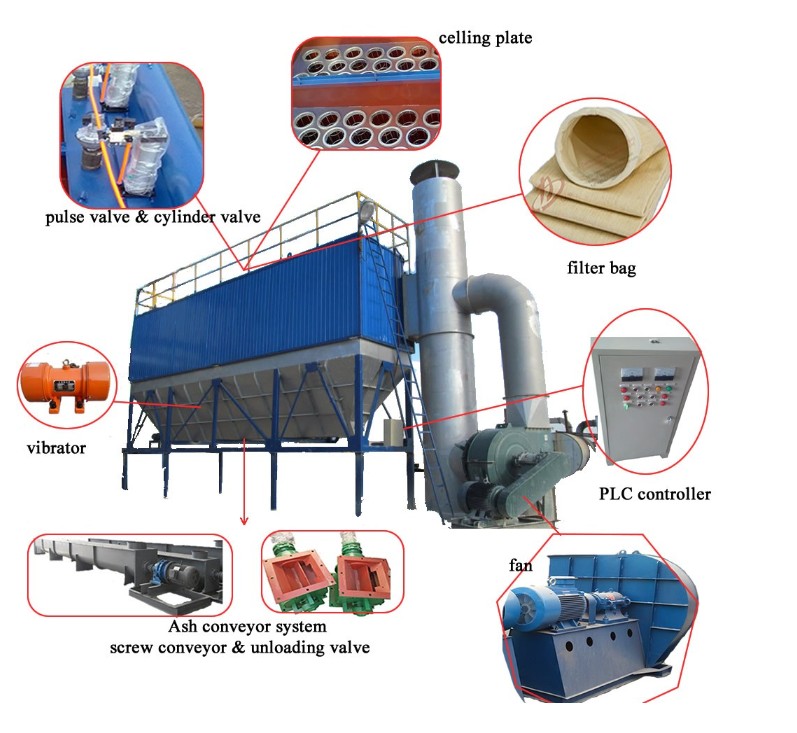

A Pulse Jet type Bag Filter consists of a Four-sided hollow metallic body which is conical at the downside. Bag filters are the oldest and mot common filter technology used to capture dust in a stream of gas typically air. The use of SCR units or selective catalytic oxidation SCO units.

RING TOP BAGS are stocked in sizes 1 2 3 4 8 9 12 with galvanized steel rings. The shap limitations.

The design should include an extra compartment to allow for reserve capacity and inspection and maintenance of.

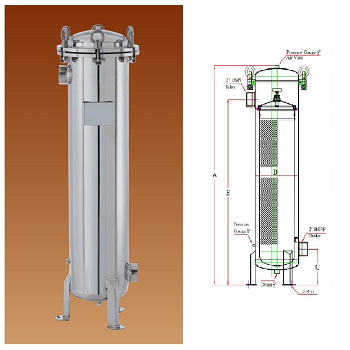

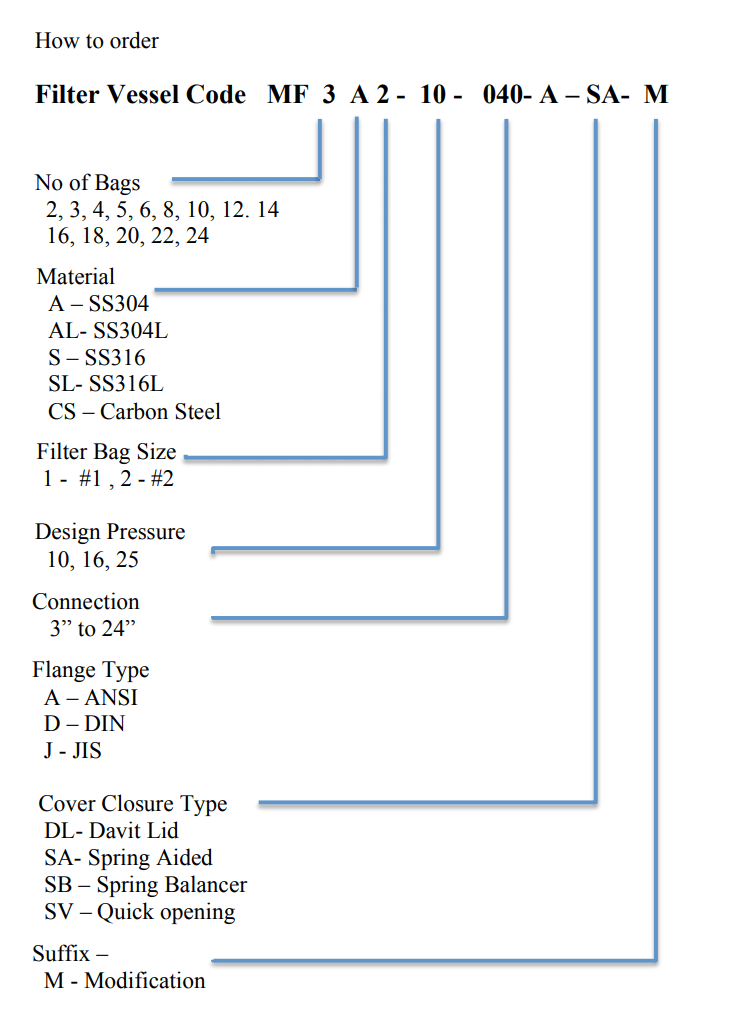

Bag filter and dust collector design software. We are a leading manufacturer and global supplier of Bag Filter Housing equipment for industrial filtration process filtration. Required filtration area calculation filter sizing. I am new member and kindly if there are any calculations or design corelations of design the bag filter. HANDLES are standard on all bags. Fabric Filter Design Variables 20-395 3-3 The total pressure drop equals the pressure drop across the filter plus the pressure drop across the cake and is given as. Be warned that some catalysts may increase PCDDPCDF production so care must be taken in the selection of catalysts. Required filtration area calculation filter sizing. There is no single value for bag reach but typical units have a value of 3 or 4.

Working principle of bag filter is explained below. A Pulse Jet type Bag Filter consists of a Four-sided hollow metallic body which is conical at the downside. Pt pf pc 3-3 pt k1vf k2 ci vf 2 t3-4 Use equations 3-3 and 3-4 only as an estimate of pressure drop across shaker and reverse-air cleaning baghouses. Bility is called bag reach and is the maximum number of rows from the nearest walkway. In this video I have explained about design calculation of Bag filter with an example by which one can easily calculate the various data of the Bag filterH. When it comes to dedusting a gas stream cartridges filters can have strong advantages compared to conventional bag filters especially in terms of filtration area in a reduced volume. RING TOP BAGS are stocked in sizes 1 2 3 4 8 9 12 with galvanized steel rings.

Posting Komentar untuk "Bag Filter Design"